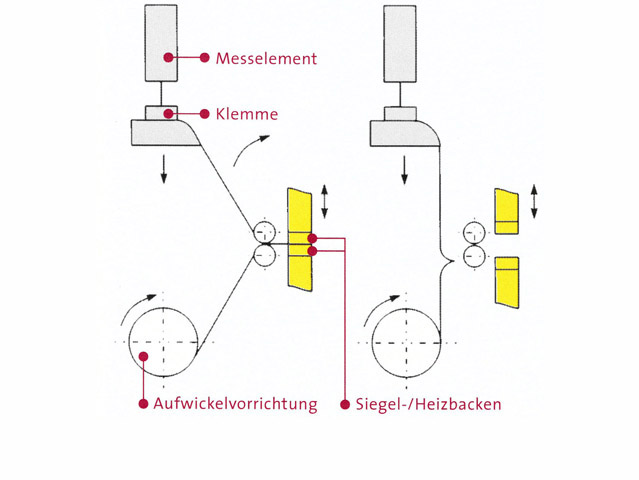

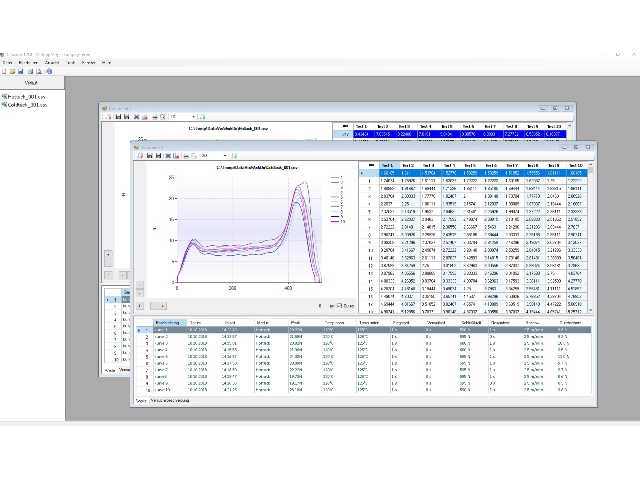

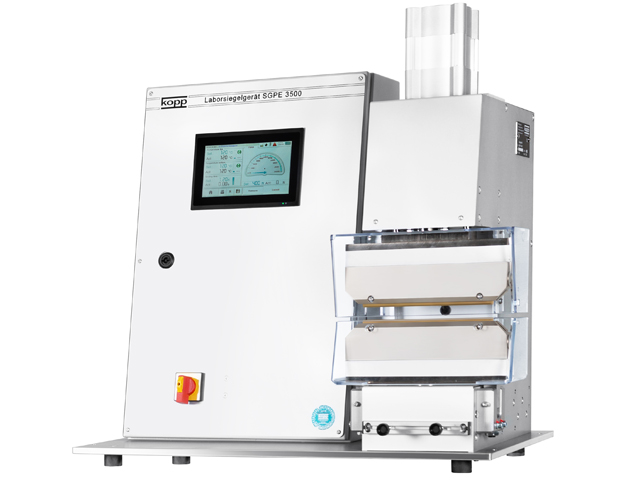

Labor-Prüfgerät zur Ermittlung der Siegelnahtfestigkeit (Warmnahtfestigkeit – Hottack und Kaltnahtfestigkeit – Coldtack).

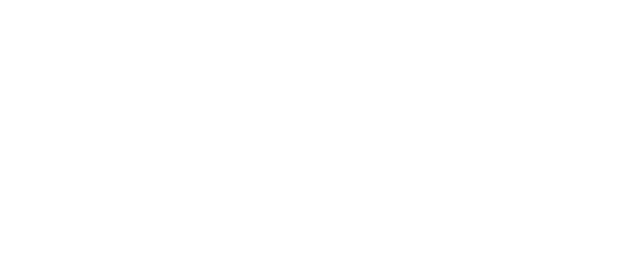

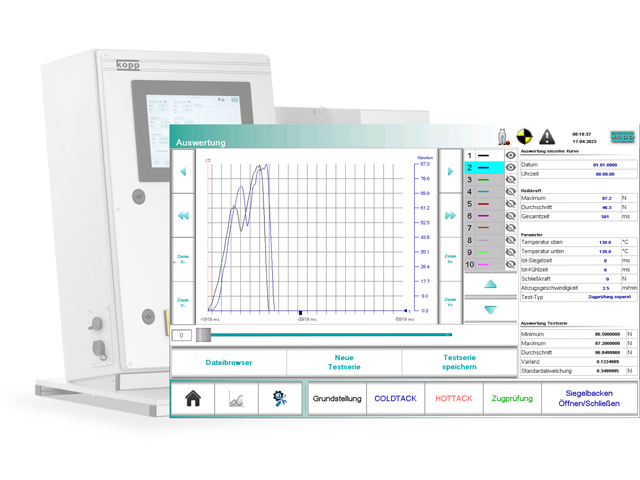

In einzigartiger Weise verbindet der Labormaster 3500 die Funktionen eines vollwertigen Labor-Siegelgerätes mit denen einer Zugprüfmaschine.

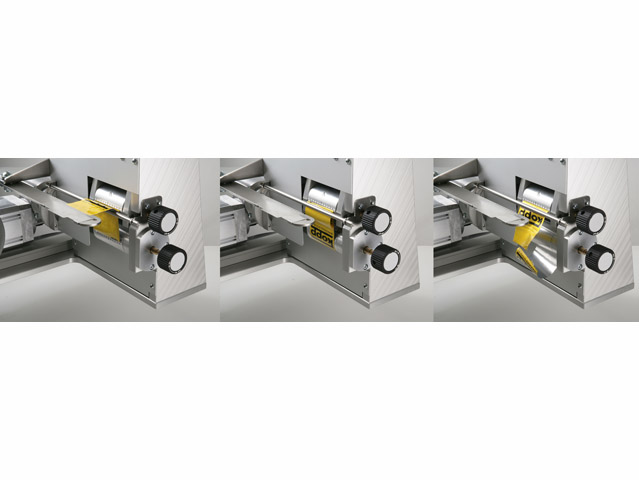

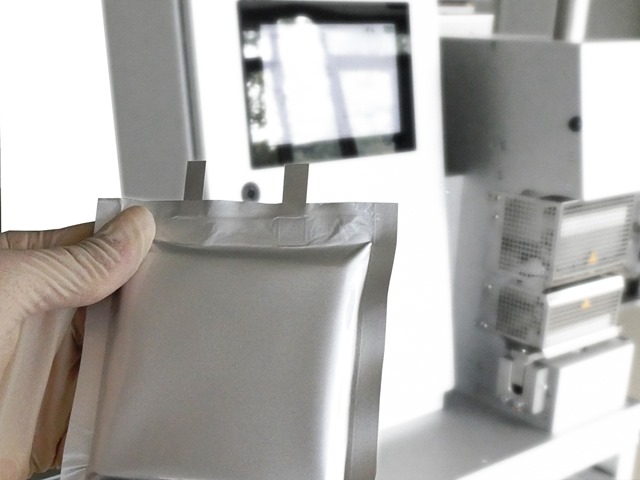

Nach der Siegelung mit exakt definierten und kalibrierten Siegelparametern: Siegelzeit, Siegeltemperatur oben und unten sowie Schließkraft wird eine echte Hot-Tack-Messungen nach der Kraftmessmethode gemäß DIN 55571-2 durchgeführt. Auch Messungen der Siegelnahtfestigkeit nach einer definierten Abkühlphase sind möglich.